Moldex3D eDesign offers designers an easy-to-use package to validate their designs behind the desk. The interactive interface, which facilitates the part and mold modeling and provides auto meshing technology, enables users to have efficient model preparation and also allows to work in CAD environment with no need for advanced CAD knowledge. The accurate 3D model allows you to obtain product insights, visualize flow and thermal properties, and optimize processes before physical parts are built. Moldex3D eDesign helps companies to design products with quality, reduce development costs, and shorten time to market.

Validate Your Design using Moldex3D eDesign

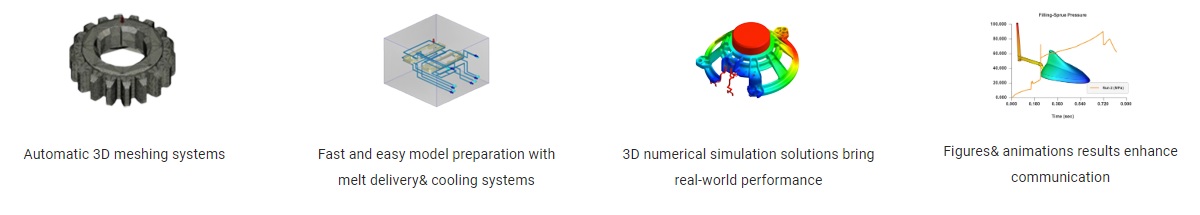

Model a part with complete runner and cooling systems within few clicks

The pre-processer Designer provides an interactive interface for users to build their parts with ease. Wizard tools guide you through steps of develop melt delivery system including sprues, runners, and gates, and building coolant channels and moldbase, with automated error detection. The auto meshing tools simplify the model preparation and allow designers to validate designs efficiently.

Perform 3D numerical analyses with accuracy

The powerful 3D solution tackles complex injection molded parts with high reliability. Designers are able to obtain the in-depth appearance and detect potential defects from comprehensive analyses. The Material Database and Process Wizard allow users to easily iterate on design changes and optimize their processes in early stages.

Generate reports automatically and present results in multiple ways

Post-processing tools enable users to demonstrate molding process and product properties with real-time contours, graphs and animations. From the automatic report generator, you can benefit on quick reports and efficient communication. Moldex3D brings you confidence in your design and helps you in successful decision making.